What is the LCD display optical bonding?

Welcome to SUNUL LCD display optical bonding Laboratories!! Possibly that you are pretty new to SUNUL, or perhaps you will be our outdated friends. We would really like to share you terrific news: SUNUL has launched a new manufacturing line, clean room, and bonding laboratories for Optical Bonding. Our vision will be to develop up new specifications as a result of our innovations that could build substantially extra added-values for our consumers.

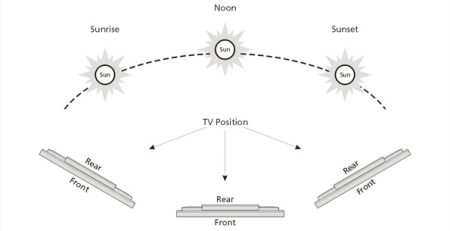

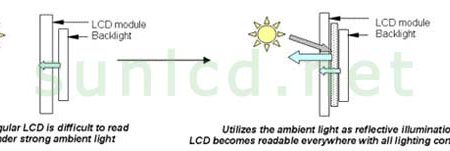

With the SUNUL optical stack, controlling reflected light appreciably improves the optical performance of an LCD display in any ambient lighting affliction. To see an LCD check in large ambient light environments and/or direct sunlight 1 need to think about two significant factors “luminance” and “illumination”. The luminance of an LCD display is its brightness. Brightness is typically referred to as a “nit” , a unit of measure, which is the quantity of light power coming out of the display. Illumination would be the amount of ambient light shining onto a show. The readability of a display is dependant within the quantity of light that may be currently being reflected off the show.

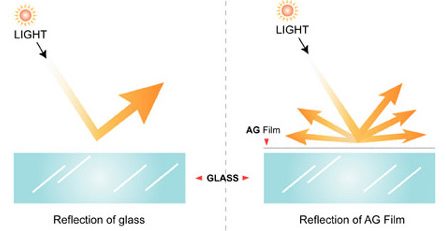

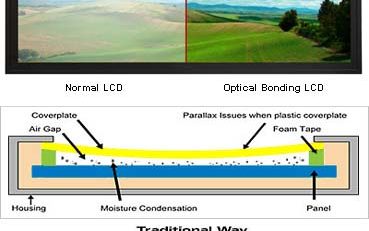

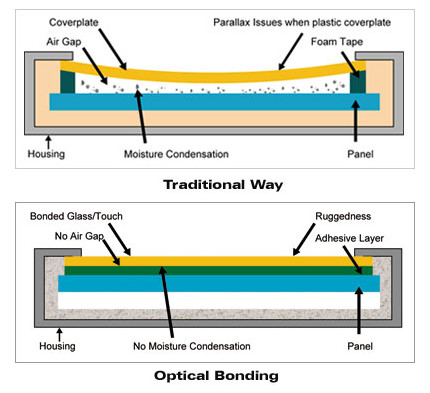

Light has the capacity to travel through a number of transparent resources; such as air, glass, plastic, and in many cases water. The material’s capability to transmit light is measured by its indices of refraction. As light transfers from one substance to yet another, such as air to glass, the differences with the index of refraction will bring about reflection. Within the situation of an air-to-glass interface, the reflection will be slightly much less than 5% in the ambient light. All surfaces that have an index “mismatch” will reflect cumulatively. In the situation of a normal glass or plastic protective overlay window, commonly employed before the delicate LCD, you will find 3 surfaces by having an index mismatch that may make a complete reflection of almost 15% on the ambient light. If your complete reflection (in nits) is near for the displays brightness, the contrast on the show is going to be diminished towards the point in which the display’s readability is reduced to unacceptable amounts.

Any sunlight readable keep track of integrated with our SUNUL procedure is equipped that has a UV protected reliable, transparent bond. This process permanently bonds the front protective glass overlay or touch display directly to your frontal encounter in the show. SUNUL’s one of a kind optical bond eliminates reflection in the two internal layers and utilizes an adhesive that matches the index of refraction from the flat panel as well as overlay. At the same time, the outer surface on the protective window is chemically handled with anti-reflecting coatings which matches the front surface on the glass together with the index of refraction of air. This mixture decreases the total reflection on the display and front cover glass to less than 2% on the ambient light. A reduction of reflection of this degree, all but eliminates reflective reduction in many ambient lighting disorders. With reductions of this level, displays with 250 to 450 nits of brightness (cd/m2), traditionally not viewable in direct sunlight, will now be readable in quite high ambient brightness or indirect lighting problems. This process also removes all air gaps, therefore decreasing the number of inner reflecting surfaces which can result in considerable degradation with the LCD’s optical effectiveness.